Who we are

Quality and competence serving professional woodworkers

Termolegno was founded in 1994. In just two decades, thanks to the reliability and the absolute efficiency of its systems, the Company is recognized, world-wide, among the most important leading manufacturers of wood dryers in industry of primary wood processing.

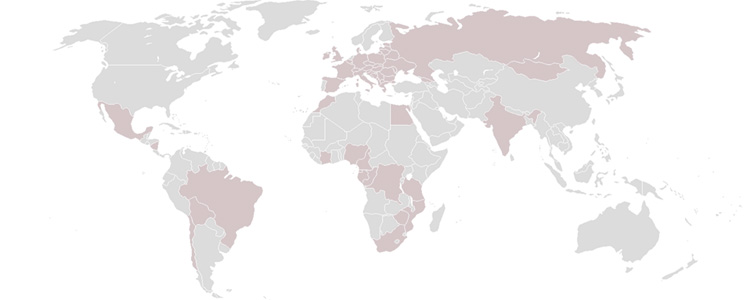

Operating in more than 60 countries, Termolegno Company offers to its customers design, production and installation of machines for drying, steaming and HT heat treatment (ISPM-15) of the wood. Each type of service is designed and developed by the company to meet the exact customer requirements and many different environmental scenarios. This allows then to provide products with high standards of efficiency and quality that guarantee a greater longevity of the system compared to those of the competition.

EXPERIENCE

made in Italy

-

We believe that the road to be favored is that

of quality, of service and innovation,

for this we aim to be present and available

to the customer with innovative services and able to

respond to the needs of the partners. -

2019

Termolegno celebrate 25 years in business and invite 60 among, agents, clients, collaborators and friends to introduce the new company activities.

2010Start of the online service, for information about the drying cycle, steaming and/or Heat Treatment (HT) in progress.

2007Second extension of the production area.

2004Research dedicated to the drying process of Pinus radiata.

1998First extension of the production area.

1996First Export experiences in Russia.

1994Termolegno is born.

Philosophy

Quality: common added value

Men and women who through their passion for their work, give life to installations by the unmistakable quality.

High quality, professionalism, research and service are the bearing foundations on which the philosophy of Termolegno rests.

The choice of the highest quality materials and the constantly update expertise of Termolegno designers, combined with the professionalism and experience of the technical assembly workers, ensure that our systems maintain over time both efficiency and reliability, allowing the customer to avoid so every possible economic and time burden caused by any suspension of the production and by constant unplanned maintenance.

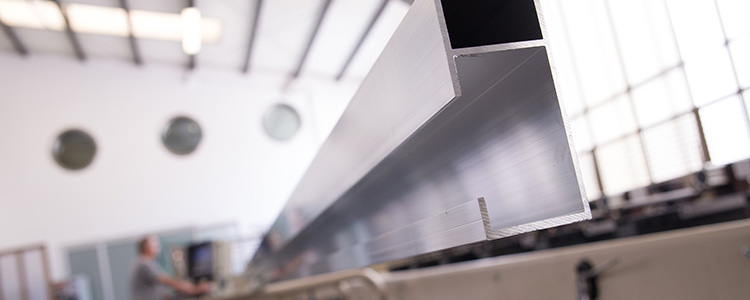

Tech design

A functional, High quality, efficient and technologically advanced product.

We believe that the road to be favored is that of quality, of service and innovation, for this we aim to be present and available to the customer with innovative services and able to respond to the needs of the partners.

Termolegno aims to ensure the best possible implementation, satisfying every need of its customers. Thanks to continual investment in the latest technology Termolegno designs and manufactures increasingly functional drying kilns, which allow customers considerable energy savings, optimized drying cycles and finished products of the highest quality.

The numbers

-

65

countries in the world -

over 25

years of experience -

35

representative agencies

in the world -

25

exhibitions dedicated to the industry and the marketing of wood each year -

8.000 m2

production area -

1

only family

Methodology and strategy

- Customized technical and commercial consulting

- Technical feasibility

- Designing the most appropriate solution and processing of working drawings

- Italian production ad hoc

- Assembly and installation on site by skilled technicians

- Test and verification of good functionality of all installed components

- Training to the operator to drying

- Tele-assistance / support / follow-up / delivery of spare parts and advice on drying technology

Design and Production

What are the needs of the end user?

The customer is the main actor in the implementation of the final solution.

It is precisely to answer this important question that Termolegno projects are the result of a thoughtful analysis of customer needs. Our technical staff responsible for marketing the systems puts the customer as the main actor in the implementation of the final solution. Collected all the basic data, the most suitable project is then processed on the basis of a feasibility study and a careful control of the essential factors of the project.

Made in Italy

All processing and raw materials (aluminum and stainless steel) that characterize the production of drying kilns for wood of Termolegno are strictly "Made In Italy". Professionals from the craftsmanship that develop their creativity in our business workshops thereby creating unique products and 100% Italian design.