Products

-

Structure, coating and insulation system

Termolegno uses an aluminum alloy extremely resistant to corrosion caused by tannins released by wood. The walls and roof are completely non-flammable and non-hygroscopic.

-

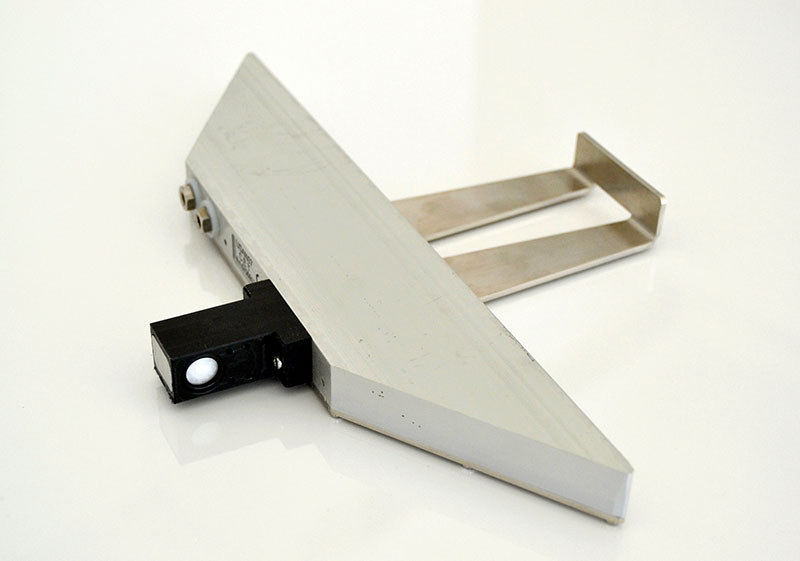

System for the replacement of saturated air

Termolegno uses reversible fans with axial fans type in cast aluminum, electric motors IP55 class H resistant to high temperatures and humidity.

-

System for the replacement of saturated air

Termolegno dryers are equipped with fireplaces with fans for air extraction. They ensure a complete exchange of saturated air and a better quality of drying.

-

Control technology

Termolegno provides a control software for Termolegno drying kilns which allows a complete control and monitoring of the drying cells, connectable with up to a maximum of 32 units.

-

Optional solutions

Termolegno solutions are designed to save time, for an optimization and a management of cycles with updates in optimal times.

-

Technical assistance and after sale

Quality services to the customer. Our technicians at the end of the assembly require a little training dedicated to the operators of drying, combined with an after-sales service with different solutions.

countries

news & events

-

DUBAI WOODSHOW 2024

Visit us at Dubai WoodShow 2024 from the 5th to the 7th of March, Stand A-23

find out more › -

TERMOLEGNO X PR FESR 2021-2027

DESCRIZIONE DEL PROGETTO

find out more › -

TERMOLEGNO AT FUTUROPALETTES 2023

find out more › -

TERMOLEGNO AT DREMA 2023

We are ready to welcome you at our Stand 36 - Pavilion 5C at the DREMA Fair in Poznan, Poland. See you there from the 12th to the 15th!

find out more ›